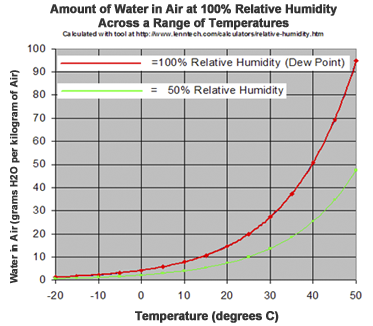

THE INEVITABLE MOISTURE

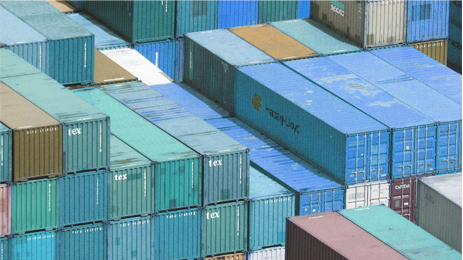

Millions of containers are shipped on the oceans around the world, through all kinds of weather, temperature and humidity.

CARGO AND CONTAINER SWEAT

Moisture frequency is normally defined as cargo sweat or container sweat.

CARGO DAMAGE

Moisture in the container can cause damage on several levels.